SEDEMI celebrates 46 years of experience and success in the Ecuadorian market. Since its foundation in 1977, it has been a benchmark in the construction sector, standing out for its excellence and commitment in the development of great projects. Its history began in Cantón Rumiñahui, with a small industrial maintenance shop, which, thanks to the entrepreneurial vision and hard work of its founder Rafael Proaño, has become a large company with more than 900 direct employees, 500 indirect employees, an industrial plant of 90.000 square meters and solid experience in the execution of more than 5.000 projects around the country.

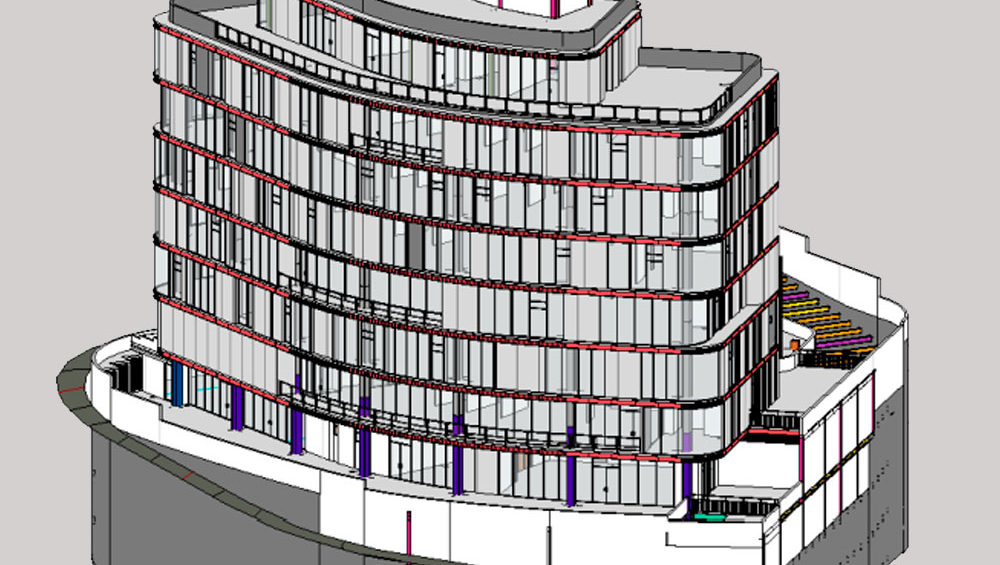

With a clear vision, the company has established itself in Ecuador as a benchmark for innovation, evolving, and transforming traditional construction processes into Construction 4.0. Under this concept, SEDEMI has been using the BIM Methodology (collaborative construction model), Industrialized Construction (automated and controlled production) and integral management (ERP) for several years -three essential trends in modern construction- with the certainty that companies that do not digitize will be left behind.

During these 46 years, SEDEMI has focused on quality, safety and sustainability, ensuring that each project meet the highest standards. Its business model based on specialization and integrality allows SEDEMI to serve efficiently various sectors such as: Urban, Industry, Mining, Oil & Gas, Energy and Telecommunications, with products and services that exceed the expectations of all its customers.

One of the fundamental pillars of the company has been its highly qualified and committed employees. The company’s team have been essential to the achievement of its goals and the maintenance of its reputation as leaders in the sector. As mentioned by its President Esteban Proaño: “The company recognizes and appreciates the dedication of all its employees throughout these years, since their passion and experience have been essential to successfully face the challenges of each project”.

On this anniversary, SEDEMI reaffirms its commitment to continue building a better country, promoting sustainable development and the digital transformation of the industry.